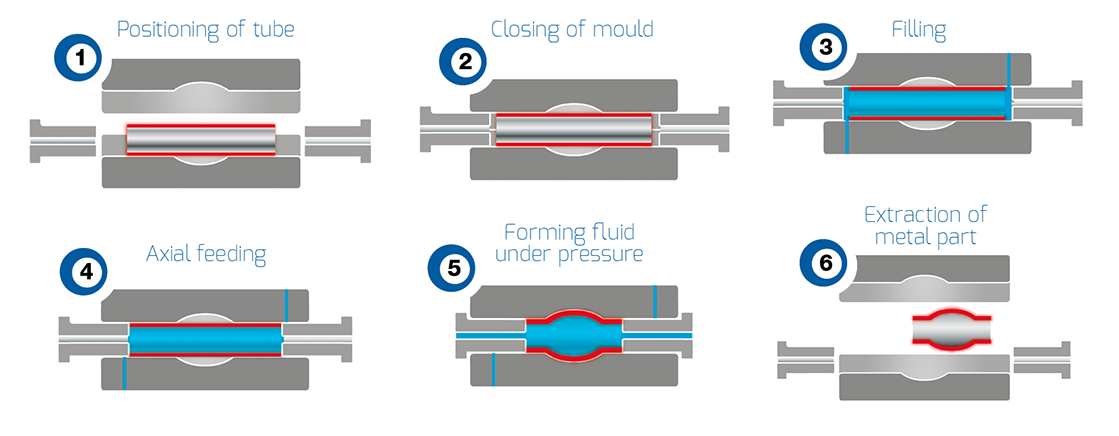

Thanks to this technique the designers have a total freedom to be creative: tubes hydroforming, in fact, allows them to obtain complex shapes that usually required more expensive and complex processes, such as casting.

In the stainless steel tubes machining, hydroforming is a revolutionary process that allows to obtain extraordinary results, with obvious advantages in terms of time and costs.

The hydroformed tubes reach much superior aesthetic and functional quality levels to those obtained with traditional processes. The hydrostatic pressure, that deforms the tubes, ensures that every single part has endured the same uniform pressure and, consequently, the absence of spring-back as well as great reliability and rigidity.